◆ GYMK Automatic Flexo Printing and Slotting Die-Cutter --Page 1

◆ GYK-C High Speed Automatic Printing Slotting Machine --Page 2

◆ ZSYC Automatic Feeding Printing and Slotting Machine --Page 3

◆ ZYM Automatic Feeding Printing and Die-cutting Machine --Page 4

◆ Single Face Corrugated Production Line (Light Type) --Page 5

◆ Single Face Corrugated Production Line (Heavy Type) --Page 6

◆ Single Face Corrugated Production Line (Adsorption Type) --Page 7

◆ QDF Automacic Cardboard Laminator (Refacer) --Page 8

◆ SBF Cardboard Thin Blade Slitter Scorer --Page 9

◆ Printing and Slotting Machine ZSYC-D --Page 10

◆ High Speed Rotary Die-Cutting Machine --Page 11

◆ Automatic Feeding Rotary Die-Cutting Machine --Page 12

◆ Creasing and Die-cutting Machine --Page 13

◆ Semi-auto High Speed Stapler --Page 16

◆ 3 ply Corrugated Board Production Line --Page 19

◆ 5/7 ply Corrugated Board Production Line --Page 20

◆ Automatic Laminator --Page 23

◆ Pallet Jack & Glue Machine --Page 24

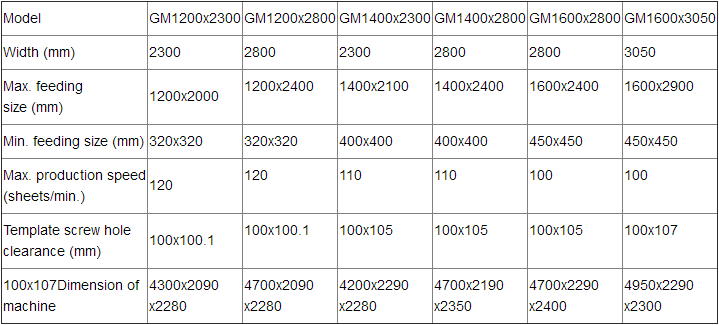

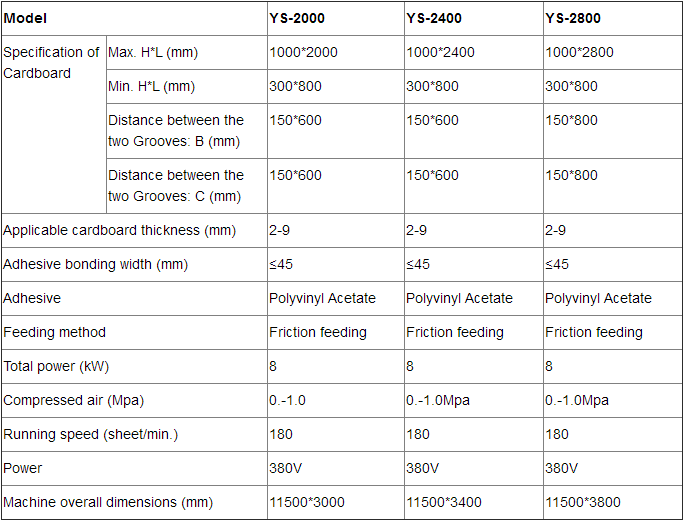

Technical Specification:

Model |

ZSYC-D 1200x2200 |

ZSYC-D 1400x2600 |

ZSYC-D 1400x2800 |

ZSYC-D 1600x2800 |

ZSYC-D 1800x3200 |

Max. feeding size (mm) |

1200x2000 |

1400x2400 |

1400x2650 |

1600x2600 |

1800x3000 |

Min. feeding size (mm) |

350x350 |

350x350 |

350x350 |

450x450 |

500x500 |

Max. printing size (mm) |

1150x1800 |

1350x2200 |

1350x2400 |

1550x2400 |

1750x2600 |

Max. slotting size (mm) |

7x300 |

7x350 |

7x350 |

7x400 |

7x450 |

Max. slotting clearance (mm) |

100 |

110 |

110 |

120 |

130 |

Slotting blade thickness (mm) |

7 |

7 |

7 |

7 |

7 |

Standard printing plate thickness (mm) |

7 |

7 |

7 |

7 |

7 |

Max. machine speed (sheets/min) |

80 |

70 |

70 |

60 |

50 |

The machine adopts chain feeding for cardboard, cardboard to be fed manually.

--Page 10

Vacuum sucking kick-back-type cardboard feeding system. The wind flow can be adjusted for smooth feeding

in accordance with the cardboard size and the bending degree.

The side guides is adjustable manually. The front guide will be synchronically adjusted manually for 3ply and

5ply corrugated cardboard as well as manual individual adjustment of the clearance.

Phase adjustment device, planetary gear.Mechanical type rotating rubber rollers can move left-and-right for 30mm with radial differential adjustment

device, even distribution of wearing on the rubber roller which increase the life time of rubber roller

Balance correction to increase the running stabilityAutomatic electric recording or setting output quantity.

Skip cardboard-feeding device provides the options of continuous feeding or skip feeding.

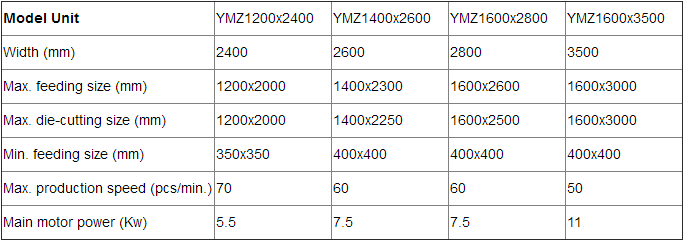

Technical Specification:

Note:The width of this machine can be in accordance with the requirement from customer, max. width up to 3500mm.

--Page 11

Automatic feeding rotary die-cutting machine is designed to solve the question that the previous chain cardboard-feeding

die-cutting machine can’t process continuous mass production, the continuous paper-feeding can ensure the cardboard

is going in the right way, increase the efficiency, greatly decrease labor intensity of workers and reduce the rate of defective

products.

Phase adjusting mechanism

Cushion roller repairing

Cutting roller pneumatic lifting mechanism

Balancing adjustment for better stability

Electronic automatically recording or setting of production quantity.

Technical Specification:

--Page 12

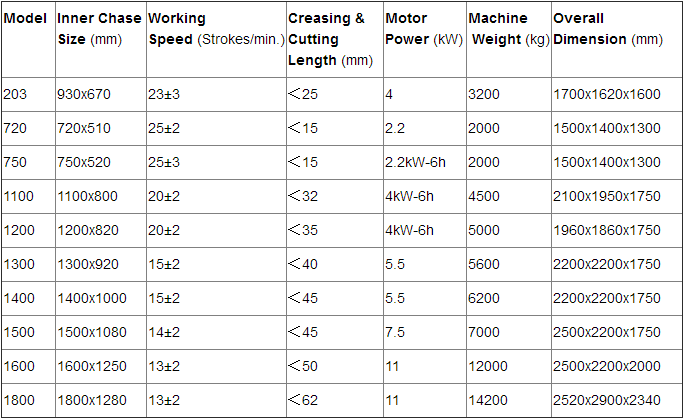

Creasing with the same specification, the machine has the structure of more reasonable design, with stable

working, low noise and higher pressing force for cutting, especially as to thick carton, plastic sheet etc.

Functions of single cardboard creasing and cutting, continuous creasing and cutting and time delay of opening,

the range of time delay of opening is adjustable.

Technical Specification:

--Page 13

Average speed of carton gluing: 5000-10000 pcs/hour

Automatic feeding, automatic glue spreading, automatic folding, automatic correction, automatic counting,automatic stacking.

Frequency control of speed adjustment, data input on touch screen.

Overcoming effectively scissor mouth and fish tail mark happened on the traditional carton gluer, ensuring

accuracy of carton gluing.

Applicable for forming a carton from one piece of cardboard.

Significant savings in labor cost and improvement of efficiency.

Technical Specification:

--Page 14

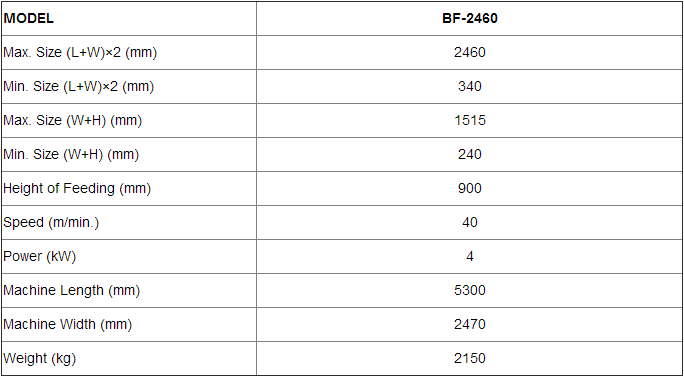

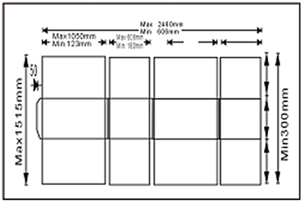

Manual folding and feeding, automatic gluing.

Easy operation. Size change quicklyMin. gluing size 240mm.

Technical Specification:

--Page 15

One minute quick order change.

Operator-machine interface control, easy operation.Indication of position of failure, easy for repairing.

Stapling completion by one time for single staple, double staplers or strengthened staple. Applicable for the

requirement to the staples from different customers.

Auto alarm device for Staple wire wrapping or running out.

Automatic counting, the finished carton can be stacked to the end of conveyor by the setting quantity (1 to 99).

Production capacity around 10000 pcs per 8 hours.

Mechanical Speed: 400 staple/min.

Technical Specification:

|

|

|

--Page 16

|

The machine is applicable for stapling various corrugated paper carton |

||||||||||||||||||||||||||||||||||||

|

The machine is applicable for stapling various corrugated paper carton. |

--Page 17

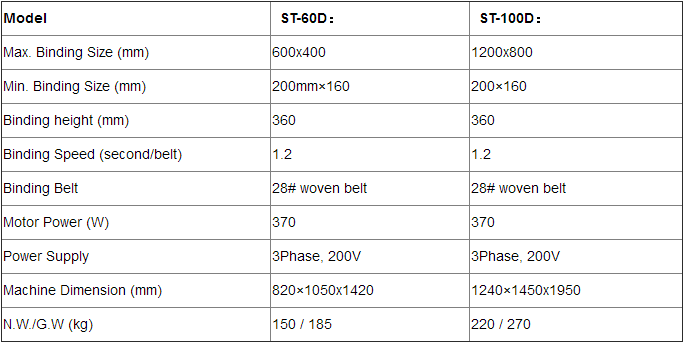

PE Packer is used for paper box, cardboard case, color printing company and so on. It replace the manual

packing machine. One worker only can operate the packer without technical training. It saves the labor cost.PE packer is suitable for cardboard box, paper product, newspaper, books, magazines and so on.

Technical Specification:

--Page 18

The production line applicable for automated mass production for 3ply corrugated cardboard, with good quality,

high efficiency, centralized control, easy operation, convenient maintenance, safety and reliability. It greatly

reduces the workers' working intensity.

Steam heating or thermal oil heating can be chosen.

The latest international energy-saving method of using high temperature thermal oil to provide heating to the

machine, with energy savings of 60% or above compared to the steam heating, will significantly reduce the

power consumption and effectively reduce the cost of production. This is the ideal economy machine of today

and applicable for medium or large sized of carton factory.

This line mainly contains shaftless holders, single facer, bridge conveyor, twice gluer, double facer, creasing

& slitting machines, transverse cutting machine, heating system and electric system.

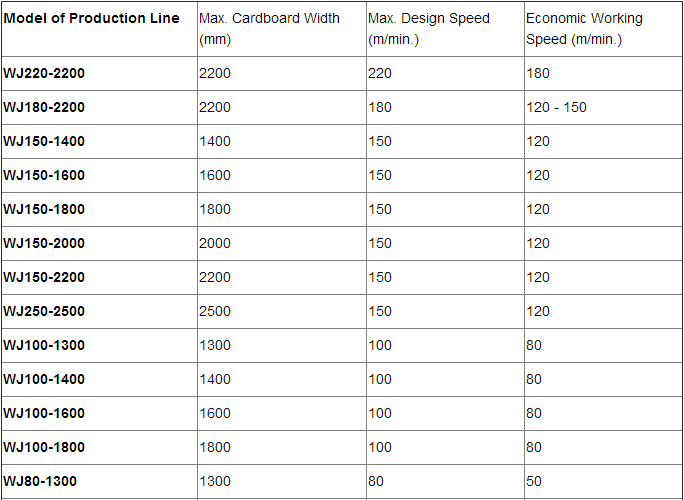

Technical Specification:

High speed line is available.

--Page 19

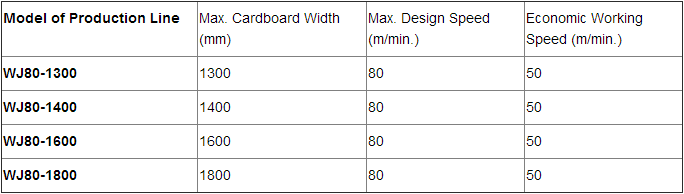

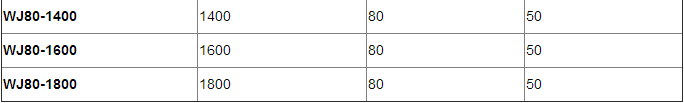

The production line applicable for automated mass production for 5/7ply corrugated cardboard, with steam

heating.

This line mainly contains shaftless roll stands, pre-heater, single facers, pre-conditioner, bridge conveyor,

gluing machine,double facer, high speed creasing & slitting machines, NC transverse cutting machine, stacker,

heating system, glue making system and electric system and son on, subject to the model and speed of

production line.

We can supply 5ply and 7 ply corrugated production line of high speed, medium speed and low speed, with

width range from 1400 mm to 2500 mm and speed range from 100m/min. to 250 m/min. Such as following:

--Page 20

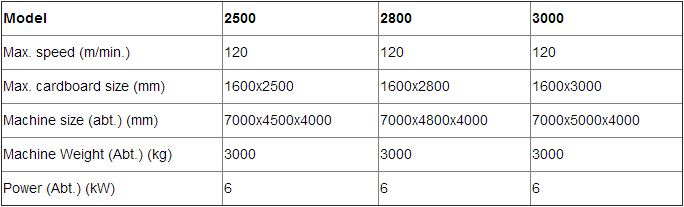

The machine is used for prompt receiving and stacking of cardboard from the Automatic Feeding Printing

Slotting and Die-Cutting Machine or Automatic Feeding Printing and Slotting Machine which have high

production speed.

1. Maximum stacking height: 1600 mm.

2. Automatic control of way of lifting up and down.

3. Pneumatic lifting up and down for the front receiving unit.

Technical Specification:

--Page 21

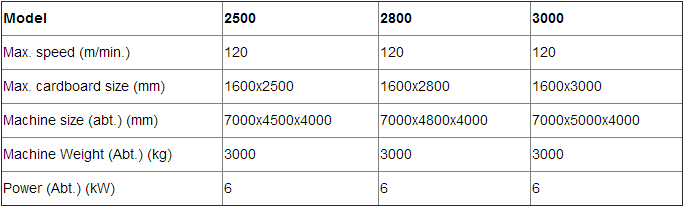

The machine is used for receiving and stacking the cardboard from Rotary Die-Cutting machine, mainly deals

with cardboard scraps from die-cutting by vibration, ensuring prompt stacking of receiving cardboard without

cardboard scraps.

1. Max. stacking height: 1600mm2. Automatic control of way of lifting up and down.

3. Pneumatic lifting up and down for the front receiving unit.

Technical Specification:

--Page 22

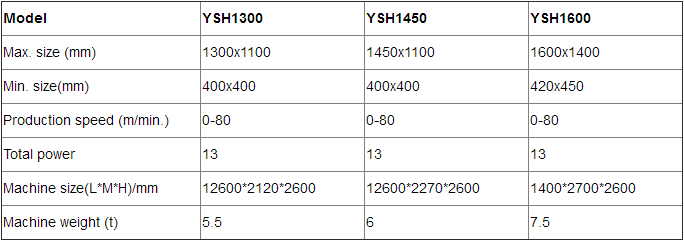

Automatic width adjustment device for corrugated cardboard, easy operation and time saving.

Imported high strength conveying belt, durable, easy maintenance.No interrupt during high speed running of the machine.

It can be used to for lamination of 5ply corrugated cardboard.

Technical Specification:

--Page 23

--Page 24