◆ GYMK Automatic Flexo Printing and Slotting Die-Cutter --Page 1

◆ GYK-C High Speed Automatic Printing Slotting Machine --Page 2

◆ ZSYC Automatic Feeding Printing and Slotting Machine --Page 3

◆ ZYM Automatic Feeding Printing and Die-cutting Machine --Page 4

◆ Single Face Corrugated Production Line (Light Type) --Page 5

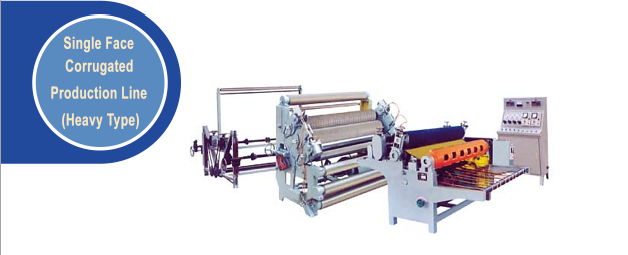

◆ Single Face Corrugated Production Line (Heavy Type) --Page 6

◆ Single Face Corrugated Production Line (Adsorption Type) --Page 7

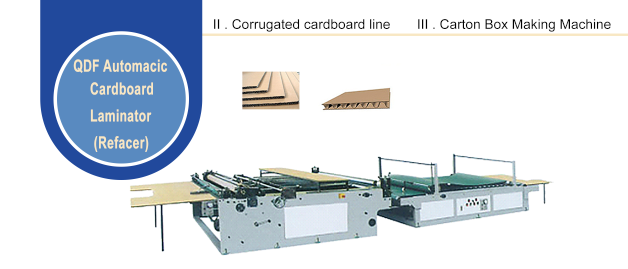

◆ QDF Automacic Cardboard Laminator (Refacer) --Page 8

◆ SBF Cardboard Thin Blade Slitter Scorer --Page 9

◆ Printing and Slotting Machine ZSYC-D --Page 10

◆ High Speed Rotary Die-Cutting Machine --Page 11

◆ Automatic Feeding Rotary Die-Cutting Machine --Page 12

◆ Creasing and Die-cutting Machine --Page 13

◆ Auto Folder Gluer --Page 14

◆ Gluer --Page 15

◆ Semi-auto High Speed Stapler --Page 16

◆ Carton stapler --Page 17

◆ PE Auto Packer --Page 18

◆ 3 ply Corrugated Board Production Line --Page 19

◆ 5/7 ply Corrugated Board Production Line --Page 20

◆ Auto Stacker --Page 21

◆ Vibrating Stacker --Page 22

◆ Automatic Laminator --Page 23

◆ Pallet Jack & Glue Machine --Page 24

Application:

Cardboard carton factory, printing factory, packing factory.

It can produce different regular printing carton and irregular printing carton, such as fruit carton, beer carton,

drink bottle carton, foodcarton, clothing carton, electronic carton and other kinds of carton.

Raw material for production:3 ply, 5 ply, 7 ply corrugated cardboard.

Main Description:

1. This machine adopts PLC program control, the frequency converter to adjust the phase mechanism, dual

operation by touch screen or push button, the controllable ink roller is intelligently automatically lifted, the

printing plate will be memory reset automatically after wiping, personalized joggling, the machine will be standby

automatically after completion of the setting quota.

2. Main drive gear made of high quality alloy steel (20CrMnTi), with program-controlled carburizing and quenching,

grinding and machining, which will be high-hardness and high-precision gear with accuracy class six (tooth surface

hardness HRC58-62).

3. Touch-screen displays setting value, to control the adjustment of each group of printing plate and the position

of slotting blades etc.

4. It has function of setting of the production rate, counting and prompts.5. The wheels for pulling and conveying of cardboard has the function of self-locking quick adjustment, to avoid

the damage to the rollers and inconvenient operation happened on the traditional screw-fastening-type device.

6. Application of keyless connection device, eliminating the gap happened on the traditional connection, to

maintain long-term printing chromatic precision.

7. Application of spray-type anti-splash device for the transmission lubricating. Lubrication system cycles

automatically, with anti-leakage device.

8. The units are locked by pneumatic cylinder between each unit. The integral machine has a strong self-locking

mechanism, to ensure the stability of the unit.

Including the following Unit:

| Cardboard Feeder | Printing Unit | Slotting Unit | Die-cutting Unit | Stacking Unit |

|

|

|

|

|

Technical Specification (5 colors printing slotting and die-cutting machine)

Model |

GYMK |

GYMK |

GYMK |

GYMK |

GYMK |

GYMK |

Max speed (pcs/min) |

180 |

180 |

160 |

160 |

150 |

140 |

Economic printing speed (pcs/min) |

140 |

140 |

130 |

130 |

120 |

110 |

Max feeding size (mm) |

1000x2000 |

1000x2400 |

1200x2400 |

1200x2800 |

1400x2800 |

1600x2800 |

Min feeding size (mm) |

280x685 |

280x685 |

300x685 |

300x685 |

350x685 |

400x685 |

Cardboard feeding thickness range (mm) |

2.5-12 |

2.5-12 |

2.5-12 |

2.5-12 |

2.5-12 |

2.5-12 |

Max printing area (mm) |

950x2000 |

950x2400 |

1150x2400 |

1150x2800 |

1350x2800 |

1550x2800 |

Standard printing forme thickness (mm) |

7.2 |

7.2 |

7.2 |

7.2 |

7.2 |

7.2 |

Power at production (kw) (abt.) |

22 |

22 |

30 |

30 |

40 |

45 |

Total machine power (kw) (abt.) (acc. to printing group) |

40 |

40 |

45 |

45 |

45 |

50 |

Technical Specification:

Model |

GYK-C1200x2800 |

GYK-C1400x2800 |

GYK-C1600x3000 |

Printing Colors |

4 colors |

4 colors |

4 colors |

Max production speed (page/min) |

140 |

120 |

110 |

Max feeding size (mm) |

1200x2500 |

1400x2500 |

1600x2700 |

Skip feeding size (mm) |

1400x2500 |

1600x2500 |

1800x2700 |

Min. feeding size (mm) |

350x650 |

400x650 |

450x650 |

Max. printing size (mm) |

1150*2400 |

1350x2400 |

1550x2600 |

Applicable cardboard thickness (mm) |

2-12 |

2-12 |

2-12 |

Min. slotting height (mm) |

100 |

100 |

100 |

Slotting depth (mm) |

0-300 |

0-350 |

0-400 |

Standard printing plate thickness (mm) |

7 |

7 |

7 |

Axial shifting of printing plate roller (mm) |

±10 |

±10 |

±10 |

Min. slotting spacing (mm) |

160*160*160*160 |

170*170*170*170 |

180*180*180*180 |

250*60*250*60 |

260*60*260*60 |

270*60*270*60 |

|

Power of main motor (kW) |

22 |

30 |

35 |

Overall power (kW) |

30 |

40 |

45 |

Note: Stacking machine (option) is recommended so that the picking up of cardboard can be as fast as the

production speed of this machine.

Characteristics:

The machine is designed and manufactured with the aims to meet the high operation requirement, reliable

function and safe.

Fast set-up and easy operation.Automatic returning to zero setting and re-setting.

Automatic balancing device for lubricating, to keep the same level of lubricant in each unit uniforms at all times

Multifunction control by PLC and touch screen

Storage of setting of common orders, ensuring fast recalling and processing to the next order during production.

Material and components of high quality are used.

Transmission gear with hardening and grinding (hardness min. 60HRC).

Keyless connection ring, to reduce the wear in the center and maintain long-term accurate printing color register.

All rollers with chrome plating to increase the hardness.

All electrical and pneumatic components in European standard or IEC.

--Page 2

Automatic feeding printing and slotting machine is designed to solve the question that the previous chain

cardboard-feeding printing and slotting machine can’t process continuous mass production, the continuous

cardboard-feeding can ensure the cardboard is going in the right way, increase the efficiency, greatly decrease

labor intensity of workers and reduce the rate of defective products.

Technical Specification

| Model | ZSYC 1200x2200 | ZSYC 1400x2600 | ZSYC 1400x2800 | ZSYC 1600x2800 | ZSYC 1800x3200 |

| Max. feeding size (mm) | 1200x2000 | 1400x2450 | 1400x2650 | 1600x2650 | 1800x3000 |

| Min. feeding size (mm) | 350x350 | 350x350 | 350x350 | 450x450 | 500x500 |

| Max. printing size (mm) | 1150x1800 | 1350x2200 | 1350x2400 | 1550x2400 | 1750x2800 |

| Max. slotting size (mm) | 7x300 | 7x350 | 7x350 | 7x400 | 7x450 |

| Max. slotting clearance (mm) | 100 | 110 | 110 | 120 | 130 |

| Slotting blade thickness (mm) | 7 | 7 | 7 | 7 | 7 |

| Standard printing plate thickness (mm) | 7 | 7 | 7 | 7 | 7 |

| Max. machine speed (sheets/min) | 70 | 65 | 65 | 60 | 50 |

1.1 Automatic Cardboard Feeding Unit (can be chosen as an optional item)

|

Screw rod adjusting device is used during cardboard size adjustment, one man operating, simple and fast. Adjustable cardboard stacking platform, suitable for various kinds of cardboard, with stable and precise feeding of cardboard. Feeding belts adopt high quality seamless rubber belt, with high friction, long life, low noise, easy maintenance and high economic efficiency. Double tension control, convenient and reliable. Anilox roller as transmission shaft, which increases the friction between conveying belts and roller, ensures stable and fast cardboard feeding. The machine includes electromagnetic clutch separating brake device. The machine adopts PLC automatic program control, with high automation. Frequency converter drives motor to realize stable speed operation. Electromagnetic clutch braking by PLC through photoelectric signal, to keep synchronization with the host machine. |

|

1.2 Cardboard feeding section

|

Automatic chain cardboard feeding The props fixes position, ensures the cardboard feeding is accurate. Automatic counting. |

|

2. Printing Unit

Planetary transmission and electrical phasing, any 360-degree adjustment in both dynamic and static condition.

The anilox roller will automatically disengage from the printing plate once machine stops.

The upper ink roller with idling system that prevents ink from getting dried when machine is running.

Colors of 1 to 4 can be combined easily.

The pneumatic self-priming ink supply circulatory system.

With lighting for the operation in the evening.

Printing roller equipped with a rapid hanging device for the printing plate

Electric foot switch is used to control the front side or opposite side of printing plate during mounting and

dismounting.

3. Slotting Unit

360 degree electric adjustment of slotting phase.

Linkage between the four slotting blades.

High quality sawtooth-type slotting blades are used to ensure slotting smoothness.

Gear wheel made of forging steel #45, with high frequency quenching.

Drive gear with keyless connection, which ensures long-term printing precision.

Dip-in lubrication ensures long life usage.

Electric shifting and pneumatic locking is used on printing and slotting units.

--Page 3

Technical Specification

| Model | ZYM1200x2400 | ZYM1200x2800 |

| Printing Colors | 3 colors (1 to 4 colors) | 3 colors (1 to 4 colors) |

| Max. machine speed (pages/min) | 60 | 60 |

| Max. size of feeding cardboard (mm) | 1200x2200 | 1200x2500 |

| Max. size of printing (mm) | 1200x2000 | 1200x2500 |

| Min. size of feeding cardboard (mm) | 320x350 | 320x350 |

| Max. size of Die-cutting (mm) | 1200x2000 | 1200x2500 |

| Blade for die-cutting (mm) | 25.4 | 25.4 |

| Thickness of standard printing plate (mm) | 7 | 7 |

| Power of motor (kW) | 11 | 15 |

| Precision for cardboard feeding | Bending degree meets the national standard, cardboard kicking error within plus or minus 1.5 mm | Bending degree meets the national standard, cardboard kicking error within plus or minus 1.5 mm |

| Precision for die-cutting | Bending degree meets the national standard, slotting error within plus or minus 1.0 mm | Bending degree meets the national standard, slotting error within plus or minus 1.0 mm |

| Precision of color register | Bending degree meets the national standard, color register error within plus or minus 0.5mm | Bending degree meets the national standard, color register error within plus or minus 0.5mm |

| Dimension of machine (mm) | 7400x3800x2500 | 7400x3800x2500 |

ZYM series of roller printing and die-cutting machines have been developed and become a new ideal production

equipment in carton production industry in recent years. The function of machine includes automatic cardboard

feeding, printing, slotting, corner cutting, edge-trimming and drilling (any shape). It has compact structure, simple

operation, convenient adjustment, advanced performance and high efficiency. This is an ideal upgrading machine

for high-grade cardboard carton production industry. Suitable for a variety of shaped cardboard boxes or cartons.

1.1) Automatic Cardboard Feeding Unit (can be chosen as an optional item)

|

|

1.2) Cardboard feeding section

|

|

2). Printing Unit

|

|

3). Die Cutting Unit

--The planetary gear structure.

--To ensure the die-cutting quality, adjusting device is installed on outside of the gear of pad roller, ensuring the liner sped of die-cutting roller and pad roller is equal.

|

|

--Page 4

This line contains of roll stand, single face corrugate forming machine and light duty rotary slitting machine. Kraft

paper in roll is the raw material, through the procedure of corrugate forming, glue spreading, conglutinating and

drying, then automatic slitting into the required dimension of corrugated cardboard.

This line is suitable for small and medium size packaging and color corrugated box production. With high automatic

extent, low electric consumption, high efficiency, easy maintenance, safety and reliability.

Technical Specification:

Paper Width (mm) |

Mechanical Speed (m/min) |

Heating Method |

Corrugated Type |

Adhesive |

Power Source / Speed Regulating Motor |

1320 |

0-30 |

Electric heating (quartz tube), LPG, thermal oil, steam |

UV/A,B,C,D,E or made to order |

Corn or starch |

3phase/380V/50Hz, 4kW |

1450 |

|||||

1650 |

--Page 5

This line contains of roll stand, single face corrugate forming machine and heavy duty rotary slitting machine.

Kraft paper in roll is the raw material, through the procedure of corrugate forming, glue coating, conglutinating

and drying, then automatic slitting into the required dimension of corrugated cardboard.

This line is suitable for small and medium size packaging and color corrugated box production. With high

automatic extent, low electric consumption, high efficiency, easy maintenance, safety and reliability.

Technical Specification:

Paper Width (mm) |

Mechanical Speed (m/min) |

Heating Method |

Corrugated Type |

Adhesive |

Power Source / Speed Regulating Motor |

1320 |

0-50 |

Electric heating (quartz tube), LPG, thermal oil, steam |

UV/A,B,C,D,E or made to order |

Corn or starch |

3phase/380V/50Hz, 4kW |

1450 |

|||||

1650 |

--Page 6

This line contains of shaftless roll stand, single face corrugate forming machine and computer slitting machine.

Kraft paper in roll is the raw material, through the procedure of corrugate forming, glue coating, conglutinating

and drying, then automatic slitting into the required dimension of corrugated cardboard.

This line uses vacuum absorption, with small amount of glue for gluing, fast drying. It speeds up the production.

With high automaticextent, low electric consumption, high efficiency, easy maintenance, safety and reliability,

this line becomes an ideal machine for small and medium size packaging and color corrugated box production.

Technical Specification:

Paper Width (mm) |

Mechanical Speed (m/min) |

Heating Method |

Corrugated Type |

Adhesive |

Power Source / Speed Regulating Motor |

1320 |

0-80 |

Electric heating (quartz tube), LPG, thermal oil, steam |

UV/A,B,C,D,E or made to order |

Corn or starch |

3phase/380V/50Hz, 4kW |

1450 |

|||||

1650 |

|||||

1800 |

--Page 7

It mainly use gluing for corrugated cardboard, paperboard and color printing face paper then becoming a new

cardboard.

It is used for food, drink, home electronic equipment, light industry, weave and gift packing industrially.Technical Specification:

Model |

QDF-1100 |

QDF-1300 |

QDF-1600 |

Max. laminating size (mm) |

1050x1000 |

1250x1000 |

1550×1000 |

Min. laminating size (mm) |

300x400 |

350x400 |

350×400 |

Mechanical speed (m/min) |

0-50 |

0-50 |

0-50 |

Power consumption (3 phase 4 line) |

382V/4kW |

382V/4kW |

382V/5.5kW |

Weight of machine (kg) |

4000 |

4000 |

4500 |

Outline dimension (mm) |

9300x1400x1200 |

9300x1600x1200 |

9500×1900×1200 |

--Page 8

Semi-Automatic cardboard creasing and slitting machine adopts manual feeding for straight cardboard, and

automatic-feeding for cross paperboard. It has the features of easy, stable adjustment, convenient repair and

maintenance.

This machine is used to cut the hard cardboard, grey paperboard bind in the book cover. It can cut the big size

cardboard into required size, and into many slots at one time, so it has high working efficiency. This machine is

necessary equipment in book binding.

Technical Specification:

Model |

SBF2200 |

SBF2500 |

SBF3000 |

Width (mm) |

2200 |

2500 |

3000 |

Max. feeding size (mm) |

2100 |

2400 |

2900 |

Min. slitting size (mm) |

120 |

120 |

120 |

Max. blade diameter (mm) |

260 |

260 |

260 |

Min blade diameter (mm) |

225 |

225 |

225 |

Power (kW) |

3 |

4 |

4 |

Creasing wheel (mm) |

4 |

6 |

6 |

Slitting blade (mm) |

3 |

4 |

4 |

Machine Dimension (mm) |

3050x1400x1350 |

3400x1250x1350 |

3950x1250x1350 |

Note: The width of machine can be made wide or narrow according to the dimension requirement by customer..

The maximum width can be 3500mm.

--Page 9