| Name: | 300 bph 5 gallon 20 litres mineral water or pure water filling plant and filling production line |

| Production capacity: | 300 bottles per hour |

| Power supply: | 380V 50Hz Thress phases |

| Total weight: | 2000kg |

| Materail of machines: | SS304 |

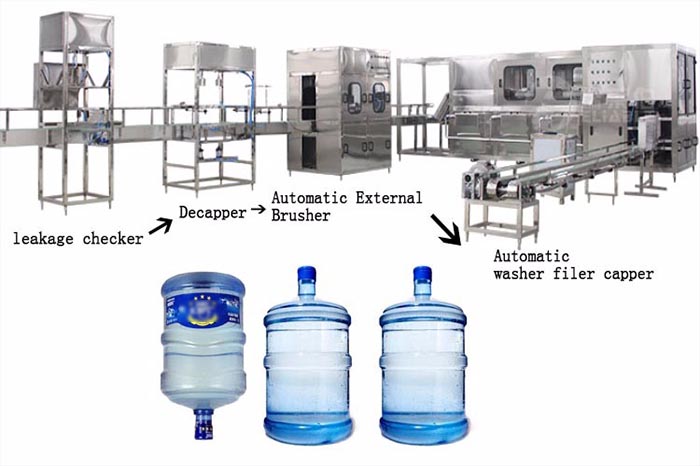

| Production process 1: | Cap De-capper |

| Production process 2: | Brush External Bottle Washer |

| Production process 3: | Washer/Filler/Capper |

| Production process 4: | Heat Shrinking Machine |

| Production process 5: | Caps Elevator |

| Fiilling liquid: | Non-carbonated drink |

300 BPH 5 gallon 20 litres mineral water or pure water filling plant and filling production line

No.1

Cap Decapper

Function: to remove the caps that

leave the 5gallon bottle that after used

1. Made in Taiwan AirTAC brand Air cylinder

2. Caps removing heads 2pcs, capacity can reach 300caps per hour

3. 304 stainless machine frame and machine body

4. With wind blowing system to gather the removed caps

5. Parameter

l Capacity: 300bottle per hour

l Machine size: 500×750×1500mm , wooden crate packing

l Machine Weight: 100Kg

l Air required 200L/M, compressed air pressure 0.6—0.8Mpa

l Power is: 0.75kw

No. 2 Brush External Bottle Washer

Function:

clean the external of 5 gallon bottles with brush and water

1. Rotary style to wash the bottle body, can washing the

bottle neck, bottle bottom, and the whole bottle body

2. Material of machine frame and body: all 304 Stainless

Steel.

3. All 304 stainless steel pipe line , valve and connector,

fine polish, no death corner

4. Linear washing style with ø350 brush 1pc ø200 brush 3pcs 300*3 brush 20pcs

5. Water pump: with 304L stainless steel pump

6. Washing

tank: size 500*300*600*1.2, 304 stainless steel

7. Parameter

l Production capacity: 300~350 bottles per hour,

l Size: 950×1200×1500mm

l Weight:

400kg

l Motor power: 0.75KW

No.3

Washer/Filler/Capper Machine 3 in 1

Function:

wash & clean internal bottle with alkali water, detergent water,pure water or other water-----filling water into empty

bottle----- capping the filled bottles with plastic caps.

4. 4- rows 10-washing stops.

Everything stop is about 23 seconds

water dripping

alkali water washing (circular using)

4th &5th are hot detergent water washing (circular using)

water dripping

circular water washing

clean water washing

water dripping

5. Separated Control Desk, one control desk to control the complete filling line

304 stainless steel construction of the control desk

set all the main control button on the desk

In-build with SIEMENS brand touch screen control panel, easy control the complete procedure of the complete line

Inbuild with day & year production quantity counter

6. 4 pcs 304L stainless steel

insert type filling nozzle, two time high precision filling, filling volume

adjustable

7. Water pump: 304L stainless

steel pump. Four washing pumps and two filling pumps.

8. SIEMENS PLC controlling

system, all full-automatic working, Shneider

& Omron brand other electric parts

9. With AirTAE brand air

cylinder, F.R.L. Combination and Electromagnetism valve for air cylinder.

10. With chain conveyor capping system ensure the

lowest miss of the capping process, no caps missing

11. With 4 pcs 304 stainless

tanks inside the machine, the washing water is circular using

12. Hot water washing system is

combined with full-automatic temperature adjuster and temperature display meter

13. Machine frame and body: all

304 Stainless Steel, combine with clear fiber glass windows

14. The machine has auto bottles

loading system and share one inlet

conveyor belt with the Brush washing internal bottles machine, Brush washing

external bottles machine.

15. No bottles no washing, no

bottles no filling, no bottles no capping

16. Parameter

Production capacity: 300 bottles per hour

Power supply: 380V 50Hz –phase (other power supply is available)

Suitable to Φ270×490 bottle ( 3,5,6 Gallon Bottle )

Weight: 1100kg

Machine Size: 2500×1800×1800mm