Sarkami filling production line

Memco Group in the Middle East is the Saudi Arabian water and juice market benchmark, the local water market is mainly used in two types of bottles, respectively, 330ml and 600ml, the bottle accounted for nearly 90% of the local water sector share. Zulal, as a subsidiary of Memco, decided to purchase the Sarkami Blow Molding Machine in an important reason that Sarki Blowing Equipment uses double-chamber production technology, as the name suggests, double-chamber production at the same time, the output will be doubled.

Memco Group asked Sarkami to provide two filling production lines, used in two vials 330ml and 600ml filling mineral water products.330ml bottle yield 95200 bottles per hour, 600ml bottle yield 60,000 bottles per hour.Taking full account of the needs of efficient and high-yield customers, two filling production lines in the production process at every stage will play its maximum effect.

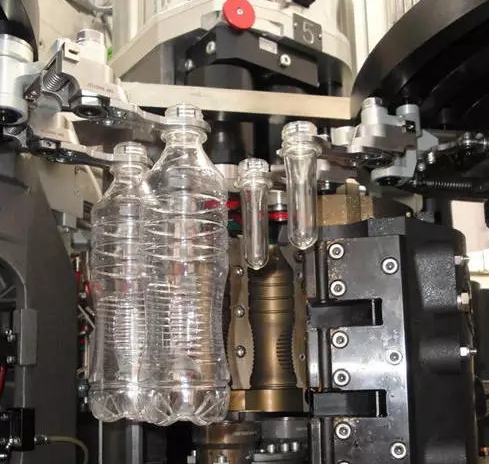

Blowing equipment in the entire production line as a soul as a pivotal role.Sarkami Blow Molding Machine SBF614 can be produced in single or double chamber depending on the size of the bottle.Such as bottle diameter less than 70mm can be used dual-cavity technology.Air clean, energy consumption, and production speed and other characteristics as a favorable factor in the market strategy, especially in the production of small or medium-sized bottles, the advantage is to play most vividly.

AWS filling machine, non-contact precision filling, that is, filling the valve and the container to maintain a certain distance, effectively prevent the filling liquid scattered splashing to the bottle, the new container gripping device easy to deal with a variety of bottle type is arbitrary.

Filling line labeling machine is essential.Carton packaging machine and Sarkami packaging developed a new palletizing robot as Zulal production line after the Road equipment.