The Basic Filling Principle Of Vacuum Filling Machine

The Basic Filling Principle Of Vacuum Filling Machine

The negative pressure filling machine (vacuum filling machine) uses the vacuum system configured in the filling machine to make the packaging container in a certain degree of vacuum, so that the liquid material in the liquid storage tank is in a certain pressure difference or vacuum state Pour into the packaging container. This filling method is divided into two forms: ① The packaging container and the liquid storage tank are in the same vacuum degree, and the liquid material is actually filled by gravity flow under the vacuum isobaric state; ② The vacuum degree of the packaging container and the liquid storage tank is different same. The former has a larger vacuum, and the liquid material can be filled under the pressure difference state; the latter can greatly improve the filling efficiency.

Since the filling is accompanied by the process of vacuuming, its structural principle is different from that of atmospheric or isobaric filling machines, and has its own unique side.

The basic principle of negative pressure filling

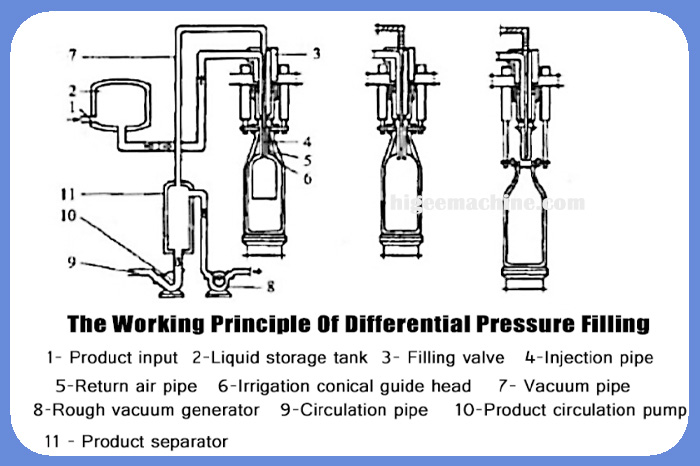

Negative pressure filling is to use the pressure difference between the liquid to be filled and the exhaust port that sucks out the gas in the container to fill, and the pressure difference can make the flow rate of the product higher than that of isobaric filling. It is especially beneficial for small-mouthed containers, viscous products or large-capacity containers, but negative pressure filling systems require an overflow collection and product recirculation device, and the foam generated by rapid filling must be discharged through the overflow system.

Filling methods with various pressure differences are derived from different forms of vacuum generation.

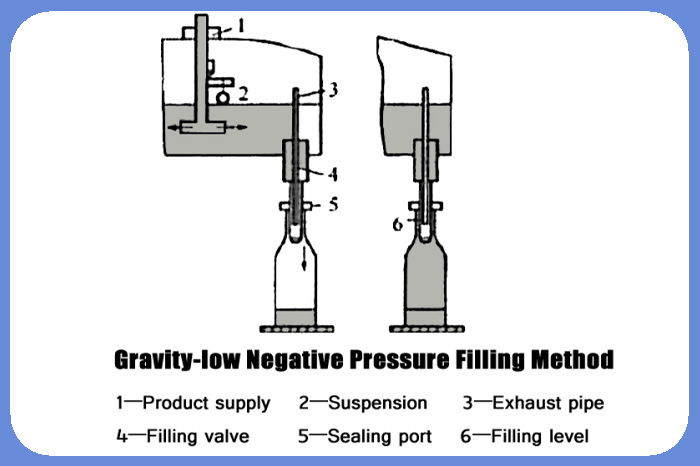

1. Gravity-low negative pressure filling

As shown in the figure below, keep the container at a vacuum level (10.1kPa~16.9kPa), and the container (usually a bottle) needs to be sealed. The low vacuum level is to eliminate overflow and backflow during negative pressure filling, and to prevent misfilling of notched and cracked bottles.

If the container does not reach the required vacuum level, the filling port will not flow out the liquid, so the bottle will automatically stop when it encounters a gap or crack. The product in the storage tank above flows through the sleeve valve into the bottle, and the pipe in the sleeve valve can be used for exhaust. When the bottle is automatically conveyed under the valve and rises, the spring in the valve is opened by pressure, and the pressure in the bottle is equal to the low vacuum at the upper part of the storage tank through the exhaust pipe, and the gravity filling starts at this time. When the liquid level reaches the exhaust port, the filling stops automatically.

This method is especially suitable for filling wine or alcohol, because there is very little turbulence and aeration, so that the alcohol concentration will not change, and the filling of high-grade famous wine will not lose its mellow product, and there will be no overflow and no backflow. But under vacuum, for some liquids with aroma, some aroma will be lost. The figure below shows the working principle of differential pressure filling by gravity filling under a low vacuum.

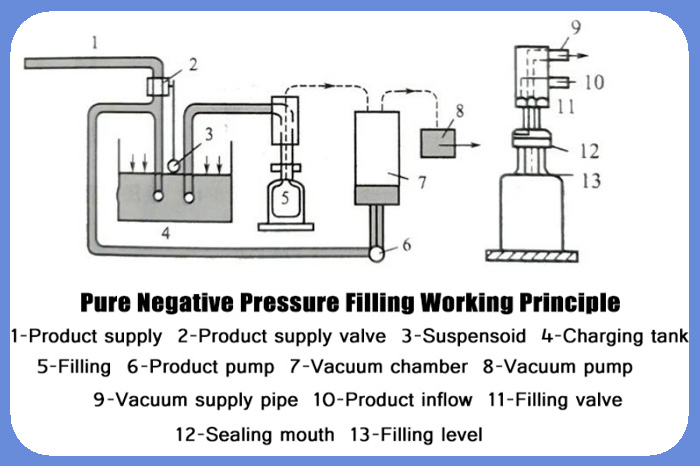

2. Pure negative pressure filling

The figure below shows a typical working principle of pure negative pressure filling. The pressure in the filling system should be below atmospheric pressure. When the sealing block of the filling valve is against the container, the valve is opened at the same time. Since the container communicated with the vacuum chamber is also vacuumed, the liquid can be quickly pumped into the container until it is filled to a predetermined liquid level. Usually, a considerable amount of liquid will be pumped into the discharge pipe at the end, and it will be recovered and recycled after entering the overflow tank.

The process of negative pressure filling: ①vacuum inside the bottle ②inlet and exhaust ③stop liquid inflow; ④remaining liquid due to flow (the remaining liquid in the exhaust pipe returns to the liquid storage tank through the vacuum chamber).

The negative pressure method can increase the filling speed, reduce the contact between the product and the air, and help prolong the shelf life of the product. Its fully enclosed state also limits the escape of the active ingredients in the product.

The negative pressure automatic filling machine has a wide range of applications and is suitable for filling slightly viscous liquids, such as oils and sugars. It is not advisable to expose more vitamin-containing liquids in the air, such as vegetables, juices and various canned food Filling sugar water, salt water, soup and so on.

Note: The low vacuum degree during negative pressure filling should be appropriate. If the vacuum is too high, it may cause the change of flexible packaging (such as PT bottle). If the vacuum is too low, the trachea on the filling valve will not draw back the liquid and air bubbles in the valve port and the wall of the return trachea, causing the valve to leak.

Higee Machinery is your reliable filling line solution partner, If you have any needs in filling capping labeling and packaging machines, please be free to contact Higee Machinery.